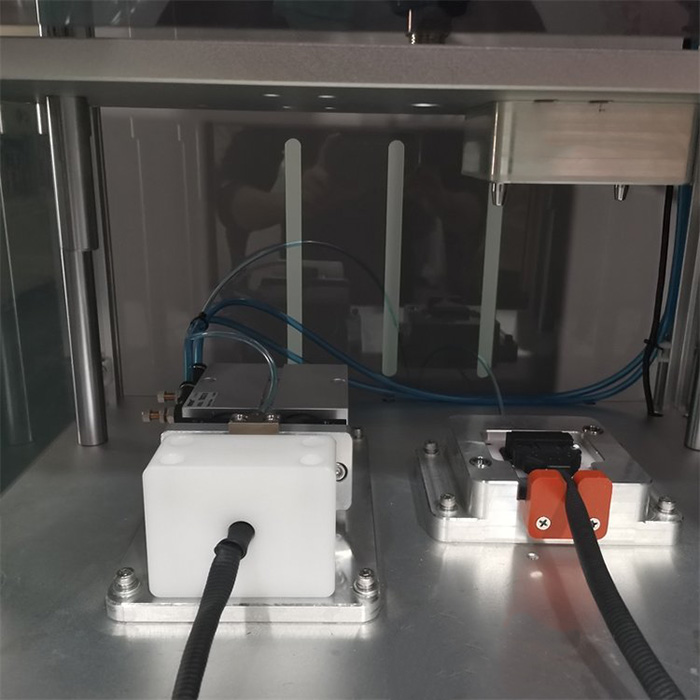

The air tightness test of outdoor lamps adopts compressed air as the test medium, and the pressure drop test method is used for the tightness test. This equipment has only (1.5cc) internal space and is equipped with a highly sensitive pressure sensor, which provides a better environment for detection and achieves high-precision detection conditions.

When the tested lamp has an air hole, it will directly supply air to the product air hole. After a certain period of time, cut off the air supply source, and use the pressure sensor inside the instrument to monitor the pressure change of the product after inflation; If the product has no air filling hole, the mold shall be designed to wrap the product, and then the mold shall be used to quantitatively inflate the product surface, cut off the air source, and use the pressure sensor of the internal instrument department to monitor the pressure change of the product after inflation to detect the IP protection level of the lamp.